MODULAR OPERATION THEATER

The Flexible prefabricated modular wall system for Ots installation has a modular grid construction. The design of the modular wall system is carried out in accordance with technical assistance and material used as per customer requirements.

1. 1.6 mm thick EGP steel panels backed by 12 mm thick Gypsum

2. PUF sandwiched panel.

3. Stainless steel SS202 or SS304 panels.

4. Hign-pressure Laminate Glass panels as per EN standard

Technical qualified and well-trained technician can perform the installation with expertise.

Fast and well-coordinated installation as per architects/customer approval Upgradation of existing systems to Modular Operating Rooms is possible Various parts are built on CNC machines to give accurate dimensions and finish.

Inside OT AC ducting and medical gas pipelining also done as per customer requirements Option of wall panel to be made of Zintex Steel Stainles Steel sheet or Stainless Steel PUF sandwich panels.

Laminar Air Flow System

The laminar flow creates a positive pressure in the OT especially giving out fresh air on the operating area. This is the area from where any kind of infection is released (from the patient’s body). The infection needs to be stopped from spreading to the OT environment. The air is quickly and continuously circulated through the exhaust system and purified through the exhaust system and purified the HEPA filters and it becomes absolutely contamination fee.

The patient being operated on Anesthetic gases and the breaths out air filled with waste anesthetic gases. This is in turn inhaled by the surgeons in a conventional air circulation system. In a Laminar Flow, the pressure in the center on the sterile zone is so much from the top that waste gases are pushed down and are diverted to the slides of exhaust vents reticulation.

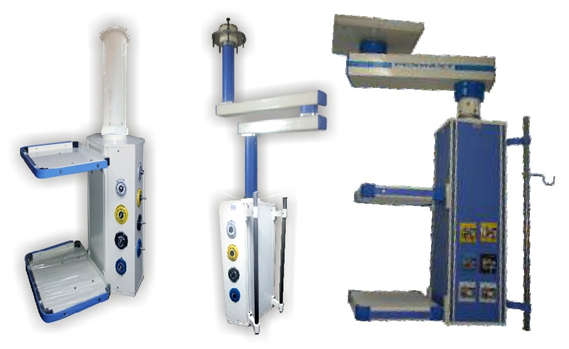

Pendant System

Ceiling Pendant designed for use in OT or ICU its closed powder-coated aluminum alloy beam contributes to improved hygiene and maximizes the working area with a hassle-free and wire-free floor space. Ceiling Pendant designed for used in OT & ICU. High-quality bearings make the arms offer wide reach and all-around to the patient and equipment especially around the back of the bed and the patient’s heads. Available in single arm or double arm configuration with manual or motorized console and power sockets and gas outlets as per user choice.

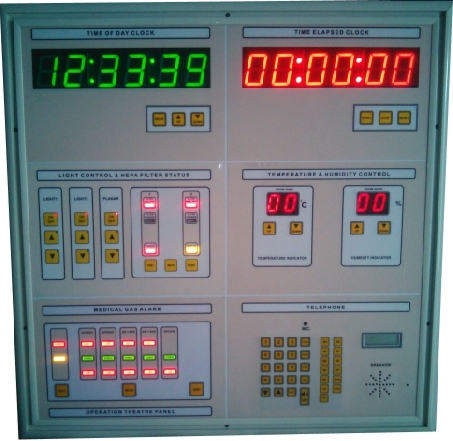

Operation Theater Control Panel

All the controls for the modular operation theater are provided on a membrane type, micro controller based electronic control panel mounted in the theatre wall. Control panel meet the electrical safety codes for high and low voltage systems. The control panel is user friendly and case of operating and maintenance purpose. The fascia is made with superior quality UV resistance membrane with sterilization feature. The control pane may consist 6 tiles or 9 tiles. We can develop the product as per requirement of customer.

1 Time of Days Clock 1 Elapsed Time Clock

1 Temperature Display/Control

1 Humidity Display/Control Lighting Control/

Dimming

1 Medical Gas Alarm Systems 1 Hands free Telephone

1 HEPA Filter Status Indicator

10T Pressure Indicator

1 Music Control

All high voltage equipment will be installed in a separate enclosure can be positioned up to 250 meter away, allowing maintenance to be carried out with minimum disturbance. The remote cabinet consists of operating lamp transformers, remote relay card, electrical distribution equipment and circuit protection equipment for all circuits within the operating theater.

Storage Unit

Easy storage possibility with wall integrated storage unit. The Zintex panels are transformed to a storage cabinet with the same anti-bacterial paint as in the OT. Covered with clear glass with Plagnetic Carcher

Pressure Relief Damper

They are placed so as to maintain the pressure in the OT. Since the AHU is pumping in a lot of air every minute and the environment is hermetically sealed. They are used to equalize the positive in the OT by opening just for a microsecond. Placed at a strategic location, so that it is not

Automatic / manual Hermatically Slide Door

We use hermetically sealed sliding doors, to maintain statically and the correct air pressure in the room, which requires less valuable space than hinged doors. The door can be operated manually or automatically with microprocessor based electronic automation system. The door frame is made out of high compact laminated board that can withstand high abrasions. The door will run on rubber rollers and guided with nylon rubber guided which are fixed to the door in such a way that they do not obstruct trolley movement through the door.

The controller will be capable of either being operated by elbow switches/foot switches, radar switch (touchless sensor). All doors will be able to be operated manually easily in the event of failure power supply or the automation unit.

Stainless Steel f1anuaI Hinge Door

To maintain sterility and the correct air pressure in the room, all doors into and outside the theater should be of the hermitically sealing type Modular Hospitech Swing door would meet following specifications :

1. Meets international quality standard & safety requirements.

2. Stainless Steel grade 304 with high density Polyurethane foam inside.

3. Noise level of movement is not more then 60 decibel.

4. Sealed with high quality neoprene sealing gasket in all edges.

5. Provided with automatic drop seal at bottom of door.

6. Door frame is made out of Thick Stainless steel 304.

7. Vision Panel in double toughened glass size 300mm x 300mm.

8. All accessories including door hinges, Handles, hardware are in Stainless Steel.

Anti Static /tonductive Vinyl Flooring

The floor finish in the operating room should be 2 mm Conductive PVC tiles, laid on a semi-conductive adhesive base. The floor finish shall terminate at the room perimeter passing over a concealed cove former and continuing up the wall for 100 mm. All joints shall be welded with electrodes of the same compatible material to provide continuous sealed surface. The floor shall have an electrical resistance of 2.5 * 10 to 106 Ohms, as per DIN 51953 ATM F-150 or NFPA 99, B1 class of fire resistance and should meet UL standard 7779. Fulfils product requirement as per EN 649.