25

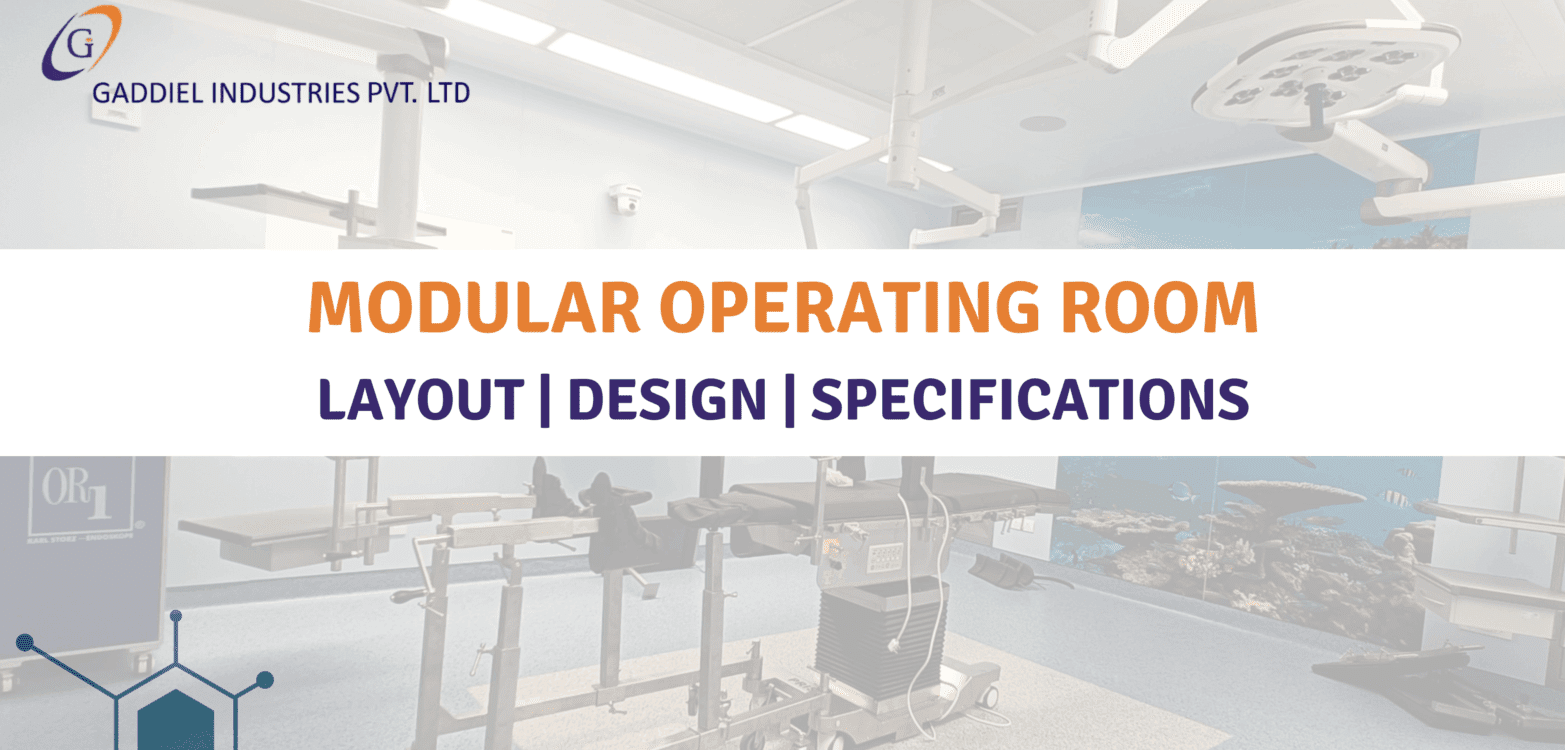

OctWith the advancement in the current healthcare setting, hospitals require surgical areas that are efficient, safe, and technologically advanced. The modular operation theater (MOT) has changed surgical infrastructure by creating hygienic and predesigned solutions that enhance patient outcomes and the experience of the surgeon.

A modular operation theater consists of prefabricated wall and ceiling panels, clean room technology, and smart engineering to produce an antiseptic and ergonomic environment. Here, we will examine the design, layout and specifications of the modern modular operation theater, along with real layout examples and guidelines for the hospital.

1. Modular Operating Room Design

Essential Components of a Perfect Modular OT Layout :

Seamless Design: Flush walls, ceilings, and integrative flooring reduce dust accumulation and promote easy cleaning.

Laminar Airflows System (LAFS): Provides an uninterrupted flow of sterile air (HEPA) providing a contamination-free environment around the surgical field.

Controlled Environment: Automatically monitors temperature, humidity and air pressure to provide the ideal surgical environment.

Integrated Equipment: Pendant, monitors, lights and gases are incorporated within the modular panels to maximize space and ensure safety.

Aesthetic & Ergonomics: Modular OTs can be designed to fit a variety of different surgical disciplines – cardiac, orthopedic, neurology, or general surgery – to ensure comfort for the surgeon and support staff ensuring productivity.

2. Modular Operative Theatre Layout

A well-designed operative theatre layout provides for an efficient workflow with minimal movement and infection control. The design should allow for easy access to all zones while still maintaining a sterile path.

Key Zones in a Operative Theatre Complex:

Non-Sterile Zone: Changing room, storage, and administrative area.

Principles of Layout Design

Accessibility: The positioning of equipment, gas outlets and electrical panels should create space.

Safety: Sufficient space around the operating table allows the surgical team and trolleys to navigate freely.

A typical modular OT design consists of an operating room with scrub station, sterilization zone, control-room and storage unit that are all connected efficiently.

3. Important Specifications for a Modular Operation Room

Every modular OT is designed using national and international standards in healthcare such as NABH, HTM 08-03, and WHO. Following are the specifications of a modular operation room that reflect quality:

| Category | Specification Details |

| Wall Panels | Stainless steel or HPL panels 1.0-1.2 mm thick, antimicrobial and fire rated |

| Ceiling Panels | Ceiling Panels GI or HPL with laminar air diffusers and light integration |

| Flooring | Conductive vinyl or seamless epoxy flooring anti-static |

| Lighting | Shadowless LED surgical light with adjustable intensity and color temperature |

| Humidity Control | 50% ± 5% RH as comfortable and safe |

| Pressure Gradient | Positive pressure in OR (15 Pa above adjacent space), with timely monitoring of pressure differential |

| Medical Gas Outlets | Oxygen, nitrous oxide, vacuum, and air outlets are integrated into the wall |

| Electrical Systems | Isolated power supply, UPS flip, and emergency lighting |

| Control Panel | Touch screen or digital control panel for controlling temperature, humidity, and lighting |

These specifications lend to patient safety, energy efficiency, and longevity of the area.

4. Important Modular OT Specifications

In addition to core infrastructure, modern modular operating rooms also have to provide various additional safety and function-related mechanisms:

- HEPA Filter Testing: Regular evaluation of air purity.

- Fire Life Safety: Fire alarms/detectors and rated finishes.

- Anti-Static Control: To prevent electrical discharge during surgery.

- Hands-Free Controls: Sensor-controlled doors and lighting for hygiene.

- Surgeon’s Control Panel: The doctor’s instrument panel can provide a clock, temperature display, laminar air flow control, and alarm status for equipment in one panel.

5. Guidelines for Current Operating Room Design

- Spatial Considerations – Consider approximately 40–60 sq. meters of OT depending on the specialty.

- Infection Control – Implement positive pressure and zoning, and clean frequently.

- Aesthetics – Include bright, calming colors and smooth surfaces to reduce tension with staff and patients.

6. Layout Suggestions for Operating Rooms

Modern modular operating rooms now include new multi-space functional spaces to improve efficiency. Therefore, some suggestions of layout include:

- Hybrid Operating Rooms: Incorporate surgical (surgery) and imaging (CT/MRI) within the operating room space.

- Ceiling-Mounted Pendants: If needed, free up floor space and usable space due to wires.

- Integrated Storage Walls: Store sterile supplies and equipment in the supply walls to organize the operating room.

- Sliding Hermetic Doors: Added to maintain pressure differentials and save space.

- Touchless Operational Systems: Create clean, easy systems of use.

Conclusion

An advanced modular operation theater is the surgery infrastructure of the future. The theatre’s innovative design, intelligent layout and specific details make it a sterile, safe, and efficient working environment for surgeons and healthcare professionals.

By utilizing international protocols and contemporary technology, hospitals can accommodate operation theatres that provide all clinical criteria, as well as patient safety and operational performance benefits.

In summary, a modular operation theatre with a well-conceived design represents more than a construction project, it is a purposeful decision on their operational efficiencies, hygiene, and quality of healthcare.