10

FebLets Explained MGPS Full Form Now…..

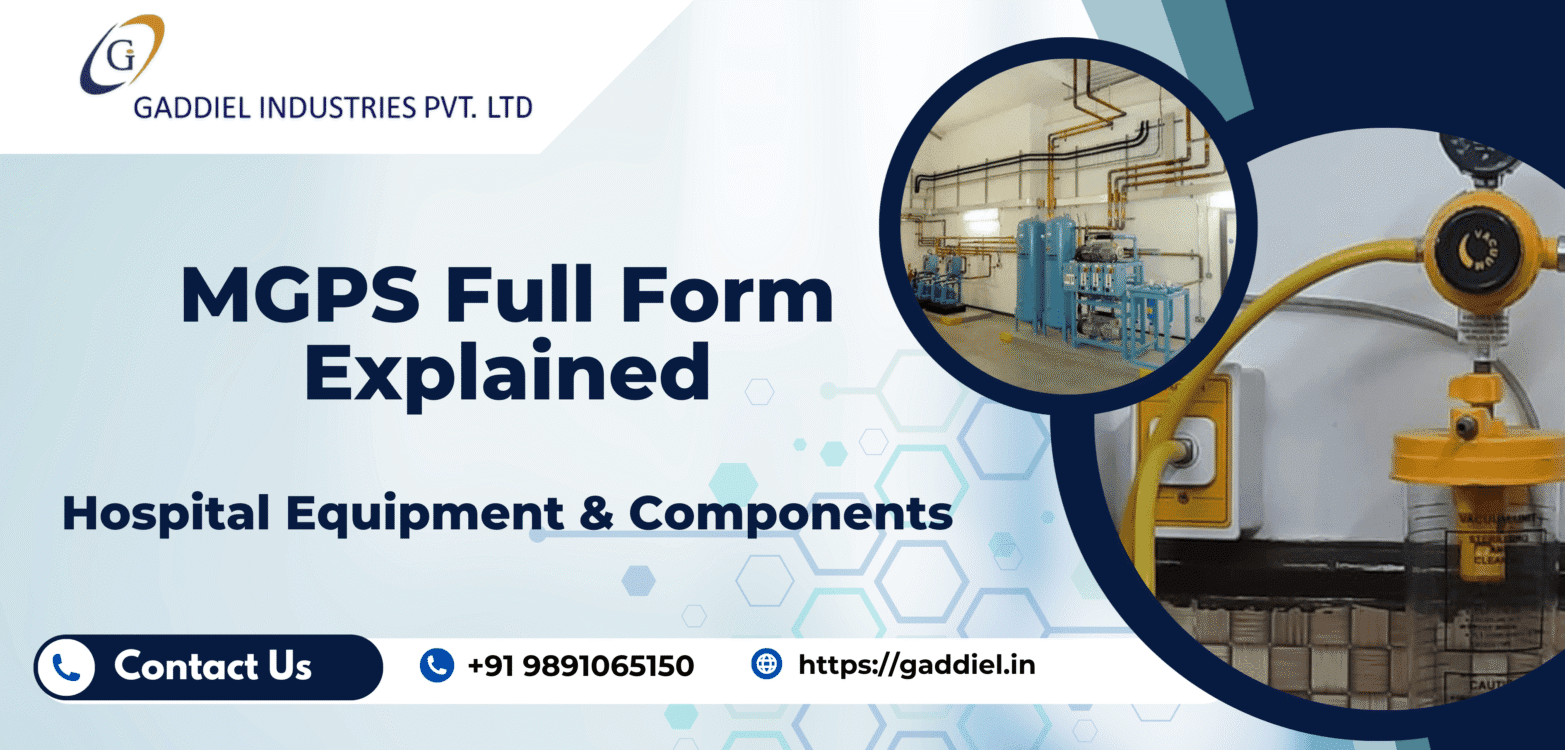

In the modern hospital, patient safety and continuous delivery of medical care are highly infrastructure reliant. One such system on which we all heavily depend and that most patients rarely know is even there, but doctors and nurses could not do without, is MGPS. From theatres to ICUs, MGPS is essential for life support gases.

In this blog post, we will focus on the MGPS full form, its significance and the essential MGPS components and equipment; furthermore, how do they together add to safe as well performance healthcare delivery in a hospital through an analysis of the importance of MGPS in hospitals.

MGPS Full Form and Meaning

The full form of MGPS is Medical Gas Pipeline System.

MGPS is a hospital-wide system that provides medical gases, such as oxygen, nitrous oxide, medical air and vacuum from a centralized point to which those departments are connected. Hospitals use MGPS to supply gases safely and constantly through a piping network, rather than individual gas cylinders next to each bed.

This product eliminates hand-holding risk, enhancing safety and preventing gas supply interruption in critical care areas.

Why Hospitals Need an MGPS

MGPS play a vital role in hospitals. Medicinal gases are just as important as drugs in surgeries and during emergency treatments. A reliable MGPS ensures:

- Continuous and stable gas supply

- Low potential for contamination or spillage

- Faster response during emergencies

- Improved patient safety and comfort

- Efficient workflow for healthcare staff

Indoor spaces such as ICUs, operation theatres, emergency rooms, and neonatal care units Shatabdi Roy et al., 2016 mainly demanded for high BTPS gas flow but occasionally small interruption in gas supply could lead to life-threatening consequences. MGPS eliminates that risk.

Type of Medical Gases provided by MGPS

A MGPS commonly delivers the gasses listed below.

- Oxygen (O₂): For respiration support

- Medical Air : Used in anesthesia and ventilators

- Nitrous Oxide (N₂O): Anesthesia, Below is a selection of gases we supply:

- Carbon Dioxide (CO2): It is used in laparoscopy

- Vacuum: For suction during procedures

There are separate pipes and interlock systems for each gas to avoid cross-connections.

Read Related – Classification of Operation Theater – Design, Function, and Level

MGPS Components and Equipment

Understanding MGPS components and equipment helps in better system planning and maintenance. Below are the main parts of a standard MGPS:

1. Gas Source

The source is where medical gases originate. It may include:

- Bulk oxygen tanks

- Manifold systems with cylinders

- Medical air compressors

- Vacuum pumps

These sources are designed with backup systems to ensure uninterrupted supply.

2. Manifold System

Manifolds automatically switch between primary and secondary gas cylinder banks. This ensures a continuous gas supply even when one bank is empty.

3. Pipeline Network

Medical-grade copper pipelines carry gases from the source to different hospital areas. These pipelines are specially treated to prevent corrosion and contamination.

4. Valves

Valves control gas flow and provide isolation during maintenance or emergencies. Common types include:

- Zone valves

- Area service units

- Emergency shut-off valves

5. Alarm Systems

MGPS alarm panels continuously monitor pressure levels and system performance. If any abnormality occurs, visual and audible alerts notify hospital staff immediately.

6. Terminal Units (Gas Outlets)

These are the points where medical equipment connects to the gas supply, such as:

- Bedside oxygen outlets

- OT gas points

- ICU vacuum outlets

Each terminal unit is gas-specific to avoid incorrect connections.

Safety Features of MGPS in Hospital Infrastructure

Safety is a top priority in MGPS design. Key safety features include:

- Color-coded pipelines for different gases

- Non-interchangeable connectors

- Pressure regulators and relief valves

- Backup gas supply systems

- Regular testing and certification

These measures ensure compliance with hospital safety standards and medical regulations.

Maintenance and Compliance

Regular maintenance is essential for MGPS efficiency and safety. Hospitals must:

- Conduct periodic pressure testing

- Inspect pipelines and valves

- Test alarm systems

- Follow national and international medical gas standards

A well-maintained MGPS ensures long-term reliability and patient safety.

Read Related – Zones of Operation Theatre: Protective, Sterile & Disposal Areas

Future of MGPS in Healthcare

As a result of hospital automation so too have all MGPS systems been developed that include convenient digital monitoring, automatic warning alerts and optimised power saving operation. With the development of medical institutions, MGPS is further advanced to become the mainstay supporting critical medical services.

Frequently Asked Questions (FAQ)

Q: What is the MGPS full form?

MGPS is an abbreviation form Medical Gas Pipeline System, it is a network of gas pipes supplying gas to hospitals.

Q: Why is MGPS important within the hospital?

No Breaks MGPS – It is essential to have a safe and continuous operation of Oxygen for optimal patient care in critical locations such as ICUs and OT’s.

Q: What is the principal components and equipments of MGPS?

They are composed of components such as gas sources, manifolds, piping systems, valves, alarm systems and terminal units.

Q: What are the Medicinal Gases that supplied from MGPS?

Typical gases are oxygen, medical air, nitrous oxide, carbon dioxide and vacuum suction.

Q: How soon does MGPS require maintenance?

MGPS should be regularly checked and maintained according to hospital safety regulations for a better performance and also compliant of MGPS.

Q: Can MGPS mitigate hospital operational risk?

Yes, MGPS/MGSS programs minimize exposure to manual cylinder handling, mitigates gas leaks risks and overall shortens patient and staff safety.